Definitions in traditional and Direct Gear Design. The purpose of this booklet is to set out the basic design for an industrial gearbox.

Pdf Dynamic Synthesis Of A Classic Manual Gearbox

As an exercise in gear selection a step-by-step procedure will be demonstrated on how to design a gearset pinion and gear for a gearbox that is to be mass produced for a general industrial application.

. Things should be made as simple as possible but no simpler This book is an attempt to apply that principle to gear design by presenting information from a manufacturing point-of-view rather than a theoretical one. And it is intended for the reader to use his own experience in selecting formulae stress values etc. Inside all the clutch drums centrifugal clutch spiders are fitted on the shaft CENTRIFUGAL CLUTCHES and rotates with it.

Shafts get larger as speeds are reduced. Design and analyze the various stresses acting on the gearbox on critical conditions of an ATV vehicle. 5 Issue 08 2017 ISSN online.

Introduction to machine tool gearboxes Design and its. A gearbox is a set of gears for transmitting power from one rotating shaft to another. The gearset shall transmit 100 horsepower at a pinion speed of 1000 revolutions per minute.

2321-0613 Automobile Transmission Systems Suyash Galgale1 Prathamesh Deore2 Ketan Pardeshi3 123 BE Student 123 Department of Mechanical Engineering 123 University of Pune Nasik India Abstract In the current world of automobile gear shifting equipped with an. Further at times measurement of vibration in the gearbox is not easy because of the inaccessibility in mounting the vibration transducers. At present much is known about gear load-carrying capacity and many complicated processes for making gears are available.

Mathematical Model of Automotive Gearbox 41 Design Variables The research object of the subject is four-speed gearbox. Gear box finds its application in Agitators conveyors crushers cranes elevators feeders small ball mills mixers cooling towers Extruders Packaging and Filters. The strength design of the gear to allow for the use a Grade 1 steel.

Design of a manually operated automotive gearbox. By using the given rotational speed of 1800 rpm input power of 10 horsepower gear ratio of 35 and an overload factor of 15 the rough dimensions of the gear and pinion were determined. Unit 01 Design of Machine T ool Gearbox.

The power is supplied by an electric motor of 10 kwrunning at 1440rpm through aV-belt. Larger gears generally use keys to transmit torque to shafts. Steps Spacers and Retaining Rings are common ways to.

In gearboxes load fluctuations on the gearbox and gear defects are two major sources of vibration. Design a gear box for a head stock to give 16 speeds ranging from 50 rpm to 1600 rpm. The calculations related to the boundary conditions.

Hence a device must be provided to permit the engine crankshaft to revolve at a relatively high speed while the wheels turn at slower speeds. Introduction to Gear Design Introduction Albert Einstein once said. This chapter begins with a comparison of the merits of spiral bevel gears and hypoid gears when employed as the final drive in the automotive gearbox ix.

For metal replacement with powder metal PM of an automotive transmission PM gear design differs from its wrought counterpart. Small pinions are often machined onto shafts. Presented here is a re-design re-building a 6-speed manual.

My Project DESIGN AND ANALYSIS OF DIFFERENTIAL GEARBOX mainly focuses on the mechanical design and analysis of gearbox as transmit the power. The gear box of an automobile can be controlled many emergency cases that does not focus on vehicle movements by changing speed and torque of the engine. Spur Gear Design.

I had developed this work as my semester project with a view to get familiar with the technologies as well as application of theories into practical work done by industries. Indeed complete reverse-engineering and re-design is required so to better understand and document the performance parameters of solid-steel vs. The constant pressure to build less expensive quieter running lighter and more powerful machinery has resulted in a steady change in gear designs 3.

The vehicle speed is also changed with the help of the transmission keeping the engine speed the same with a certain limit. Each of the chapters will deal with a-specific problem which is encountered during the design phases and during operation. A small car gear box contains four speed gear ratio and one reversegear ratio.

In traditional gear design the pressure angle is the tooling rack profile angle. Use Shims for adjustment and fine alignment of. It does not belong to one gear.

Forward gear z 1 z 2 z 3 z 4 z 5 z 6 z 7 z. Whenever the rotary motion bearings are required to support the. IJSRD - International Journal for Scientific Research Development Vol.

F Common practice in Shaft Design. This is enclosed in a metal box called a gearbox. There are no great advances in gear technology described.

If the mesh condition the center distance for example changes the pressure angle changes as well. AUTOMATIC TRANSMISSION WITH mounted on shaft A which is free to rotate on it. The gearbox design is modelled on CatiaV5 software.

Their main function is to convert the input provided by an electric motor into an output of lower. In Direct Gear Design the pressure angle is the mesh parameter. The first gear known as the driver has 12 teeth the second gear called the idler has 16 teeth and the third gear known as the driven also has 16 teeth.

Automobile Gearbox is an assemblage of gears and Shaft which is use to control output speed torque of machinevehicle. Up to 24 cash back With these major changed to the design the gearbox is still operating well and safely according to the theoretical calculations. An automobile transmission is an excellent example of how this principle is put to use in controlling vehicle motion.

The clutch springs are so designed that the 21 Field of the Work clutch spiders fly apart when rpm reaches to 500 1000 and 1600 respectively. It should help students not familiar with gearboxes lay out a reliable working design. Gearbox via analyzing supply parameters such as phase current and instantaneous power.

In gear design selected material is AISI 5160 OQT 400 which has Brinell hardness 627 yield stress 1750 MPa and ultimate tensile stress 2220 MPa. They are used in a wide range of industrial automotive and home machinery application. MECHANICAL ENGINEERING DEP ARTMENT TRINITY COLLEGE OF ENGINEERING AND RESEARCH PUNE.

The engine provides fixed speed for a certain amount of power If it is directly coupled to output shaft then it will give fixed velocity of vehicle. Figure 1 has three gears in train. Gear heads are available in different sizes capacities and speed ratios.

Gear design is a highly complicated art. The gearbox failure reasons are predicted with proper understanding and accordingly analysis is carried out. Therefore the main parameters affecting the mechanical properties of gearbox such as tooth width b gear modulus m and tooth number z are selected as design variables 7.

Pdf Direct Gear Design For Automotive Applications

Pdf Design And Static Analysis Of Automobile Gearbox Cover

Pdf Design And Calculation Of Planetary Transmission With Bevel Gears

Pdf Design And Analysis Of 9 Speed Gearbox

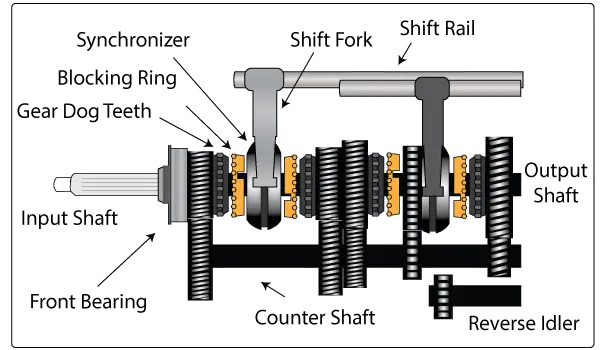

How Synchromesh Gearbox Works Best Explanation Ever Mechanical Booster

Design And Fabrication Of Gear Box Full Report Download

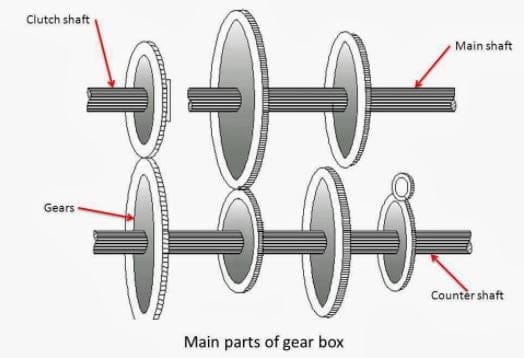

What Is Gearbox Types Parts Working Images Pdf

Gearbox Definition Parts Or Construction Working Types In Detail Function Purpose Advantages Application Notes Pdf

0 comments

Post a Comment